SKIN-PASS MILL

Excellent flatness and a perfect finish.

The advantages of skin-pass mills (temper mills) from Primetals Technologies include full compliance with tight strip elongation tolerances, excellent flatness performance, high surface quality, and the availability of wet and dry skin-passing modes. Primetals Technologies supplies stand-alone and inline skin-pass mills in either single or two-stand design for adjusting the final mechanical properties, flatness, and surface finish of strip. Thanks to its higher flatness control ability, 6-high Universal Crown Control Mill (UC-MILL) is the preferred skin-pass mill solution for meeting the continually increasing demands placed on strip flatness, elongation, and roughness, especially for hard-material grades.

Excellent flatness and perfect finish for High-Strength Steel

In addition to a single skin-pass mill in single direction, Primetals Technologies supplies two mill stands temper mill, which includes DCR (Double Cold Reduction) mills with two or even three mill stands for harder tin materials. Single or double-stand Skin-Pass Mills are placed in-line at the exit of continuous annealing and continuous galvanizing lines. 6-high UC-MILLs are supplied in response to recent requirements to roll harder material, such as hard tin plate and AHSS, with improved strip flatness control capability.

Main benefits:

- Tight strip elongation tolerances

- Excellent flatness performance

- High surface quality (roughness, peak count, low residuals)

- Wet and dry skin-passing modes

- High-speed roll changing

- Stable rolling

Want to know more? Go to Lifecycle Services & Integrated Plants & Solutions

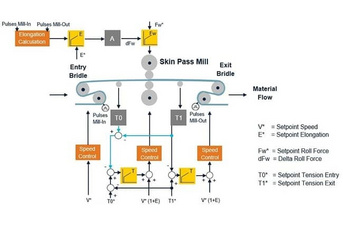

Complete automation and process control for Skin Pass Mills

Plant productivity and product quality are substantially depending on the quality of plant automation, process control, and available process optimization functions. To get the best performance out of a plant, Primetals Technologies provides add-on specific optimization solutions for further improvement of production efficiency and strip quality, besides standardized high performance automation system.

Inline Process Quality Insurances

- Strip defects follow-up with preventive defects passing strategy

- Accurate roughness and elongation controls

- Flatness Expert - Model-based Automatic Flatness Control

- Automatic Coiling tension distribution

Final Product Quality Certification

- Process data recording

- Product classification report

Integrated Plant Safety Control System

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|---|

| Flatness Expert | Flatness control for tight shape tolerances |

| Roll Eccentricity Expert | Elimination of a known strip thickness quality disturbance from rolls |

| PropertyMon | Inline measurement of steel strip properties |

| TorqueMon | Inline measurement of roll spindle torque for rolling mills |

| Position Transducer | Position measurement of rolling mill hydraulic capsule |

| Upgrade to Double Cold Reduction Mill (DCR) | Double cold reduction process for Temper Mill |

| Modular Coil Shuttle System (MCS) | Rail-based, fully automated modular coil transport system |

| Name | Short Description |

|---|

| Name | Short Description |

|---|

Reference Story: UC-MILL to achieve excellent strip shape for high strength steel without tension leveler

Customer:

Guangzhou JFE Steel Sheet Co., Ltd., China

Type of plant:

In-line Skin-Pass Mill for Continuous Annealing Line to produce HSS for automotive application

Technical Data:

Strip Thickness: 0.30 ~ 2.6 mm

Strip Width : 800 mm~1,880 mm

Mill Type : 6-high UC-MILL

Our solution:

The 6-high UC-MILL was installed to enhance the customer's product portfolio which now includes harder materials up to 1180 MPa HSS. The mill is capable of rolling such high-demand materials in wide width range and into excellent strip shape without tension leveler, to boost the plant's competitiveness.