SPECIAL STEEL MILL

Efficient rolling of hard materials.

Special steel mills are specifically designed for the rolling of hard materials such as electrical steel and other special-purpose steels. The various mill designs available include HZ mill, 12-high CR mill, KZR mill (ZR Mill with double AS-U), and 6-high Universal Crown Control Mill (UC-MILL), with small-diameter work rolls for the efficient rolling of thinner and harder materials.

Cluster mills designed to meet all product and operational needs

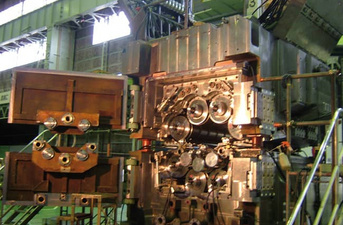

HZ Mill (Advanced Split Housing ZR Mill)

With a conventional ZR mill, there are some disadvantages, such as small roll gap opening, no force measurement, small roll diameter range, indirect-driven AGC cylinder. To address these shortcomings, Primetals Technologies has developed a split-type housing ZR mill, the HZ mill.

Features:

- Large gap opening for easy strip threading and easy recovery from strip breakage

- More free roll diameter configuration

- Shape control (Double AS-U system) for stable rolling/productivity

- High response direct-driven AGC cylinder for gauge accuracy

- Rolling force directly measured by load cell

12-high CR Mill

The 12-high Cold Roll (CR) mill was developed independently by Primetals Technologies to roll stainless steel, copper alloys, and nickel alloys. Compared with a ZR mill, there are fewer rolls and it provides greater shape control. In addition, the work roll diameter range is significantly broader, allowing for precision rolling of a greater range of materials: soft, medium, and hard.

The upper and lower back-up roll frame is split, enabling automatic work roll changing. This also ensures good strip threading performance and ease of maintenance. It is also possible to modify the housing of an existing 4-high mill to convert it to 12-high. A shift function has also been added to the intermediate roll, preventing the back-up roll contact mark from being transferred to the strip, thereby enabling the mill to be used to roll materials which have strict surface requirements.

Features:

- 12-roll arrangement (work roll x 2, IMR x 4, BUR x 6)

- Split-type BUR

- Exceptional shape control

- Small-diameter work rolls for high rolling reduction.

- Modification of a conventional mill using the existing housing is possible

Want to know more? Go to Lifecycle Services & Integrated Plants & Solutions

Complete automation and process control for Special Steel Mills

The quality of the plant automation, the process control and an optimal process determine the productivity and product quality.

To achieve the best performance of a plant, Primetals Technologies offers high performance automation systems and specific optimization solutions to improve production efficiency and strip quality.

Excellent strip quality with:

- Roll Eccentricity Expert for uniform and accurate strip thickness

- Coil Eccentricity Expert for uniform and accurate strip thickness

- Flatness Expert - Model based Automatic Flatness control

- ChatterMon / Mill Chatter Monitoring with automatic process speed adaptation

For reversing cold mills a highly optimized solution is available matching all kind of mill stand configurations. According to the complexity of production a look-up table or rolling model based mill setup can be chosen.

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|---|

| Upgrade to HYPER UC-MILL | Upgrade conventional mill to Hyper UC-MILL with minimal modification |

| Flatness Expert | Flatness control for tight shape tolerances |

| Integrated Solenoid Valve (ISV) Spray System | ISV Roll coolant spray bars for hot and cold rolling mill strip flatness control |

| Air Bearing Shapemeter | Shape measurement of rolled metal sheet and foil |

| Position Transducer | Position measurement of rolling mill hydraulic capsule |

| Modular Coil Shuttle System (MCS) | Rail-based, fully automated modular coil transport system |

| Name | Short Description |

|---|

| Name | Short Description |

|---|

Reference Story: HZ Mill - Perfect solution for high grade grain oriented silicon steel production

Customer:

ShouGang Co.,Ltd. Qian'an Iron & Steel Company, China

Type of plant:

Reversing Cold Mill

Technical Data:

Strip Width: Max 1,300mm

Mill Type : HZ Mill

Our solution:

The HZ Mill's double AS-U, intermediate roll shifting, and leveling function enabled effective strip shape control for the customer. The mill also features split housing that allows roll-open clearance, and the direct AGC cylinder that contributes to stable operation of high grade grain oriented silicon steel.